Overview

Pre-Shipment Inspection (PSI) is the last line of defense before your goods leave the factory. Conducted when at least 80% of the order is packed, PSI ensures the shipment meets the agreed specifications, quantity, and packaging standards.

Why It’s Critical for Indian Exports

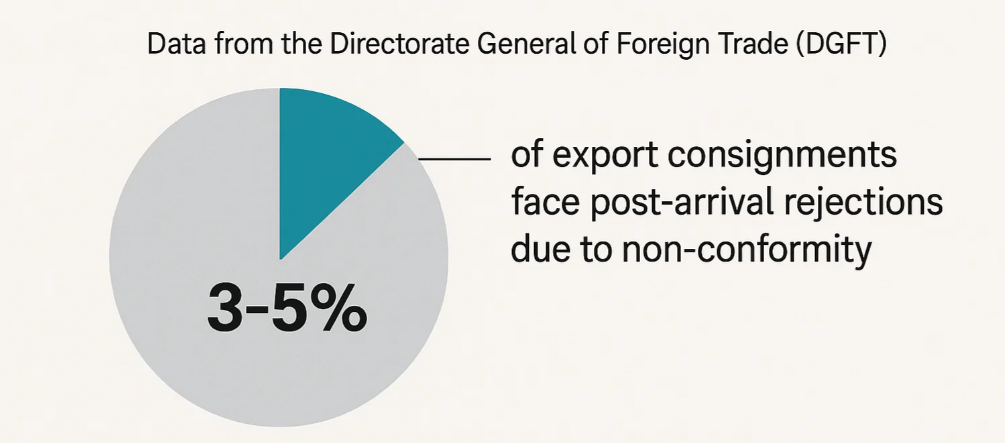

- Data from the Directorate General of Foreign Trade (DGFT) shows that 3–5% of export consignments face post-arrival rejections due to non-conformity.

- In sectors such as handicrafts, leather goods, and precision machinery, even a single rejected container can cost exporters $50,000–$100,000 in lost revenue and penalties.

What We Verify

- Quantity Confirmation – Cross-checking against purchase orders and packing lists.

- Product Specifications – Dimensions, color, weight, materials, and functionality testing.

- AQL Testing – Following ANSI/ASQ Z1.4 or ISO 2859 sampling procedures for defect classification.

- Labeling & Barcodes – Ensuring correct language, format, and compliance with destination requirements.

- Packaging Integrity – Drop tests, compression tests, and water-resistance checks where applicable.

- Special Buyer Requirements – Custom branding, promotional inserts, or country-specific standards.

Sectors We Serve

- Marble & Stone Products – Checking finish quality, edge polishing, and crack-free slabs.

- Jewellery & Accessories – Verifying design accuracy and secure settings.

- Automotive Parts – Ensuring correct part numbers, fit, and mechanical performance.

- Agricultural Products – Checking weight, moisture content, and pest-free condition.

Benefit for Buyers

PSI helps reduce return and claim rates by 50% or more, while enabling exporters to build a reputation for reliability in high-value markets such as the US, EU, and the Middle East.